Golf Course Greens Mower

PRODUCT APPLICATION

Raising and lowering the mower deck on a leading manufacturer’s golf course greens mower.

COMPETITOR

PEM replaced the mower’s hydraulic system with electric actuators.

“Whenever our company needs a new actuator, we go to PEM. We know we can count on them.”

COMPELLING EVENT

Hydraulic systems prevalent in controlling the cutting blades on the golf course greens mowers are a growing industry concern. While hydraulic systems have a number of positive attributes, they have drawbacks as well, some of which are especially problematic for golf courses. A primary concern is the fact that hydraulic systems can leak hydraulic fluid. This is catastrophic for a golf course as it kills the grass and contaminates the area. Another challenge is the installation and maintenance of the hydraulic hoses and fluids. PEM’s customer sought to differentiate their product by minimizing or eliminating the hydraulics on their greens mower.

PEM had supplied custom actuators for this particular customer’s zero-turn mowers for a number of years. When the customer initiated a project to update their hydraulics-based greens mower, the project team immediately turned to PEM for a solution.

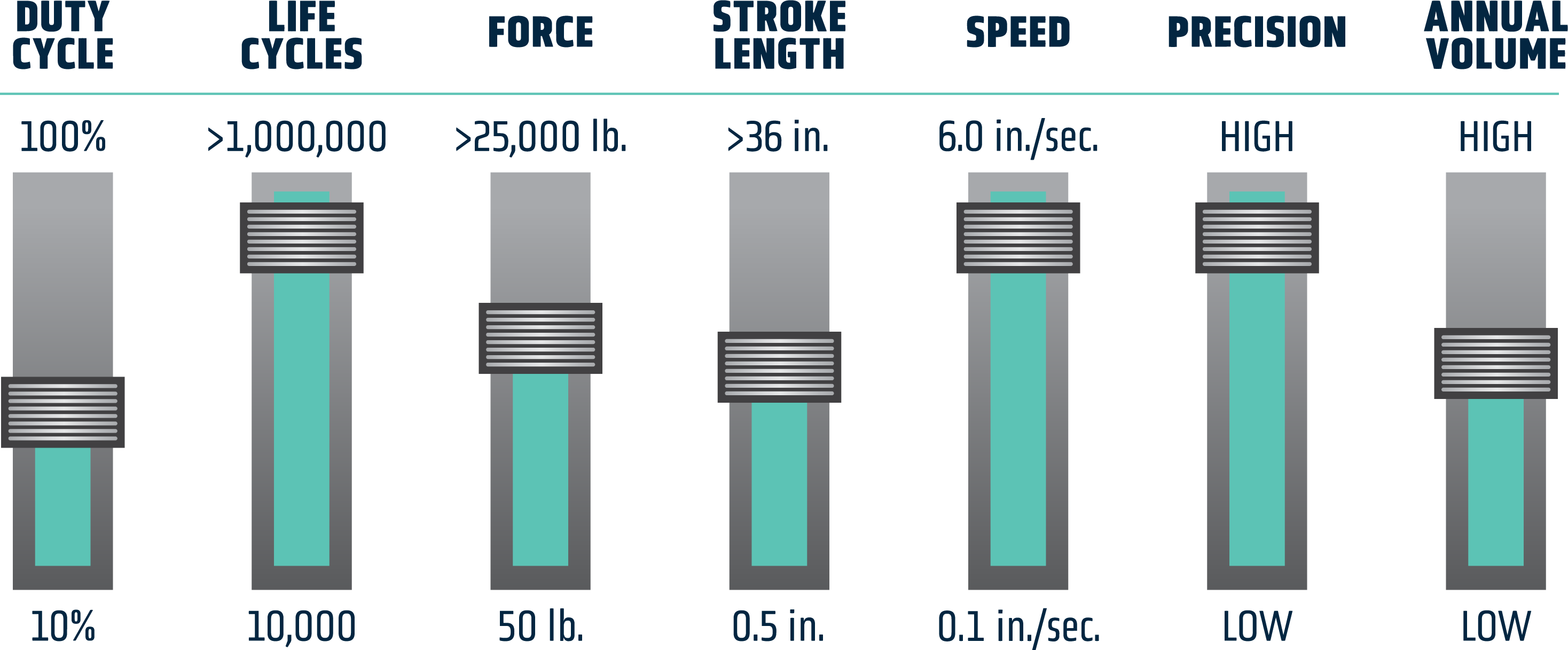

Performance requirements were stringent – heavy loads, fast and precise movement - and needing to perform for over 500,000 cycles. It was imperative that PEM’s actuator did not fail in the field or the customer’s reputation for quality, performance and reliability would suffer. This was a high-profile project for the customer. Getting golf courses to switch from hydraulics to electric was a big step in spite of the advantages. The customer made it very clear to PEM how important the project was to them. The director of engineering stated, “This is our most important project and we cannot fail. The actuator must be bullet proof”. The customer’s concern over the actuator stemmed from internal testing they did on a competitor’s electric actuator. The customer found that the competitor’s actuator used to replace their hydraulic system had a limited life span. PEM’s customer would not introduce their Greens mower with this type of performance. PEM needed to do better.

PEM went through an extensive collaborative development process with their customer. Every component was analyzed by both development teams. Every design decision was made to maximize actuator’s life cycle while meeting the performance requirements.

The prototype was completed and an extensive testing process begin. The testing process lasted for over 6 months, including numerous HALT testing, environment testing, and performance testing. Testing was successful and the product was ultimately released to the market. System performance turned out to be as good as advertised and the product launch was a successful. The electric revolution of golf courses had begun.

PEM has successfully worked with this important customer on over 6 different applications and is the vendor of choice for actuators.