Just-in-time Assistance for Commercial Floor Sweepers

PRODUCT APPLICATION

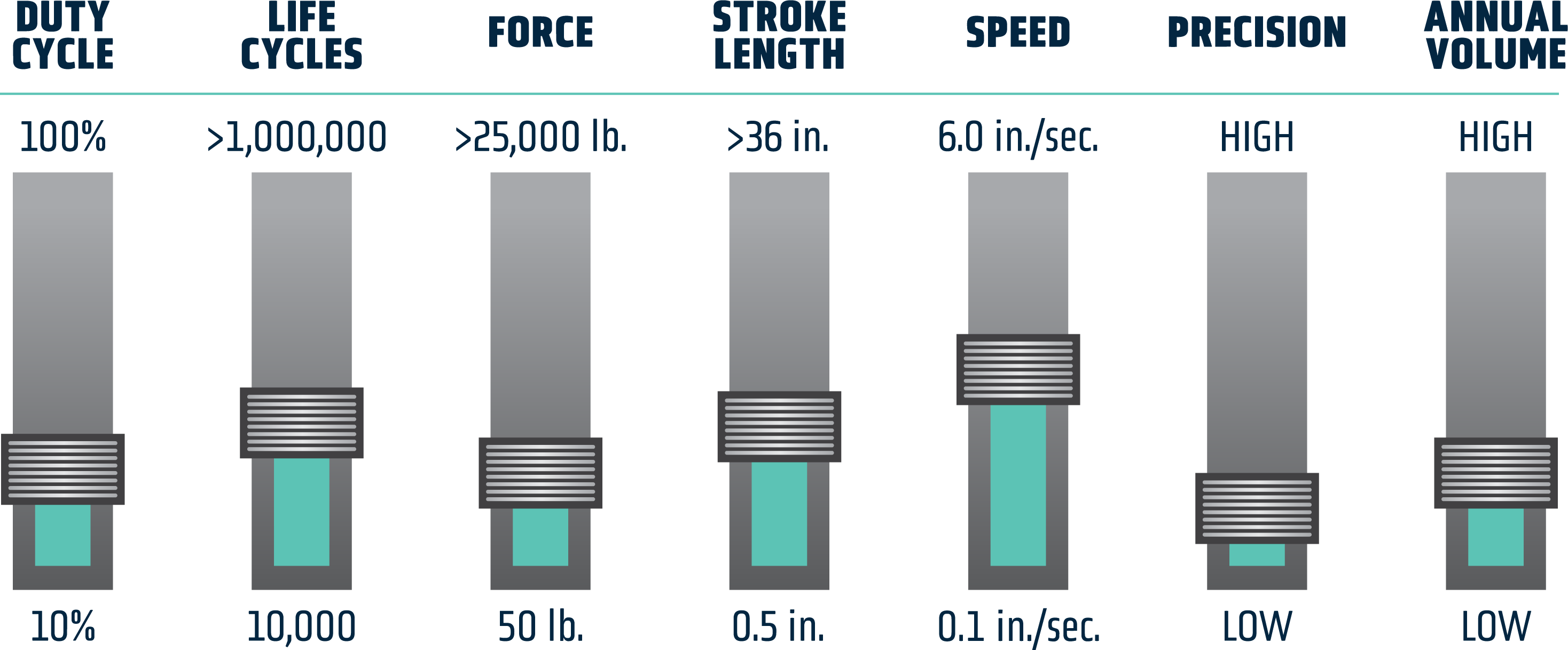

Raising and lowering the components of a floor sweeper (brushes and squeegee).

COMPETITOR

Existing supplier manufactured actuators for controlling satellite dishes, and the client had been using these actuators in their floor cleaners.

“The PEM team came to the rescue for us. Their ability to develop what we needed so quickly allowed us to get the production line back up and running at full capacity.”

COMPELLING EVENT

The incumbent actuator manufacturer transferred their manufacturing to a plant in Mexico. The transfer of the product line did not go well. Soon enough, product quality materially deteriorated and delivery times suffered. Delivery times were so inconsistent that the cleint’s production line was repeatedly shut down. The issues continued and became so bad that long-term shutdowns occurred and shipments were halted for months – the client had to shut down their lines for extended periods as well.

Issues rippled across production and supply chains creating severe brand and financial implications. A solution was needed quickly. A drop-in replacement for their existing actuators was required, and time was of the essence. The same problem actuator needed to be replaced in 10 different models. Complicating the situation was the fact that each model had relatively low annual unit volumes. Large actuator manufactures wouldn’t even consider bidding the opportunity.

PEM worked closely with the customer to determine the exact requirements on every model. PEM initiated a rush development project. PEM tooled up 50 product fixtures to quickly ramp up production. The time from initial design through tooling and product testing was 4 months. PEM then set up life cycle test fixtures and provided the customer the performance data necessary to accept the drop-in replacements. PEM shipped the first production orders just 5 months after the start of project.

In addition to the company desperately needing quality replacement product to re-activate their production lines, their supply chain needed help managing the inventory control of their multiple part numbers. The previous vendor required multi-year stocking orders for the different models. This required significant inventory commitments from the customer. PEM implemented a Just-in-Time delivery process with the customer. PEM stocked for the individual models and shipped to customer as needed. The customer established Minimum and Maximum levels, and PEM ships within 24 hours after order receipt. PEM took control over the inventory and kept production lines running smoothly. PEM worked closely with supply chain personal to develop and implement an inventory control system that minimizes the customer’s inventory while keeping production lines operating smoothly.

This project started in the mid 1990’s with 8 different actuator models. PEM continues to supply all of the customer’s actuator requirements. The relationship has grown – today PEM supplies over 20 different models that meet the customer’s exact technical, quality and inventory requirements.