Critical Environments Damper Control

PRODUCT APPLICATION

Precision HVAC valve control in laboratory and hospital room control systems.

COMPETITOR

Off-the-shelf actuator from one of the industry’s largest suppliers.

“PEM’s ability to work collaboratively with our both our engineering and manufacturing teams allowed us to replace our previous supplier with a lower cost and higher performance product that significantly benefits our position in the market.”

COMPELLING EVENT

The incumbent’s standard off-the-shelf actuator shipped with a standard electrical connector that the customer did not want in their system. The customer needed to perform a second operation to cut the competitor’s wires and then install a different connector to the actuator. This required significant unnecessary effort in the customer’s production line. The customer requested the vendor to modify their standard product to incorporate their preferred electrical connector. The vendor was unwilling to consider any modifications to its standard product in support of the customer’s request.

PEM was already manufacturing actuators for critical HVAC environment applications and approached the customer for an introduction. The timing of PEM’s introduction coincided with the customer’s growing frustration with the existing vendor’s lack of customer service. The customer was willing to look at an alternative source for the actuator.

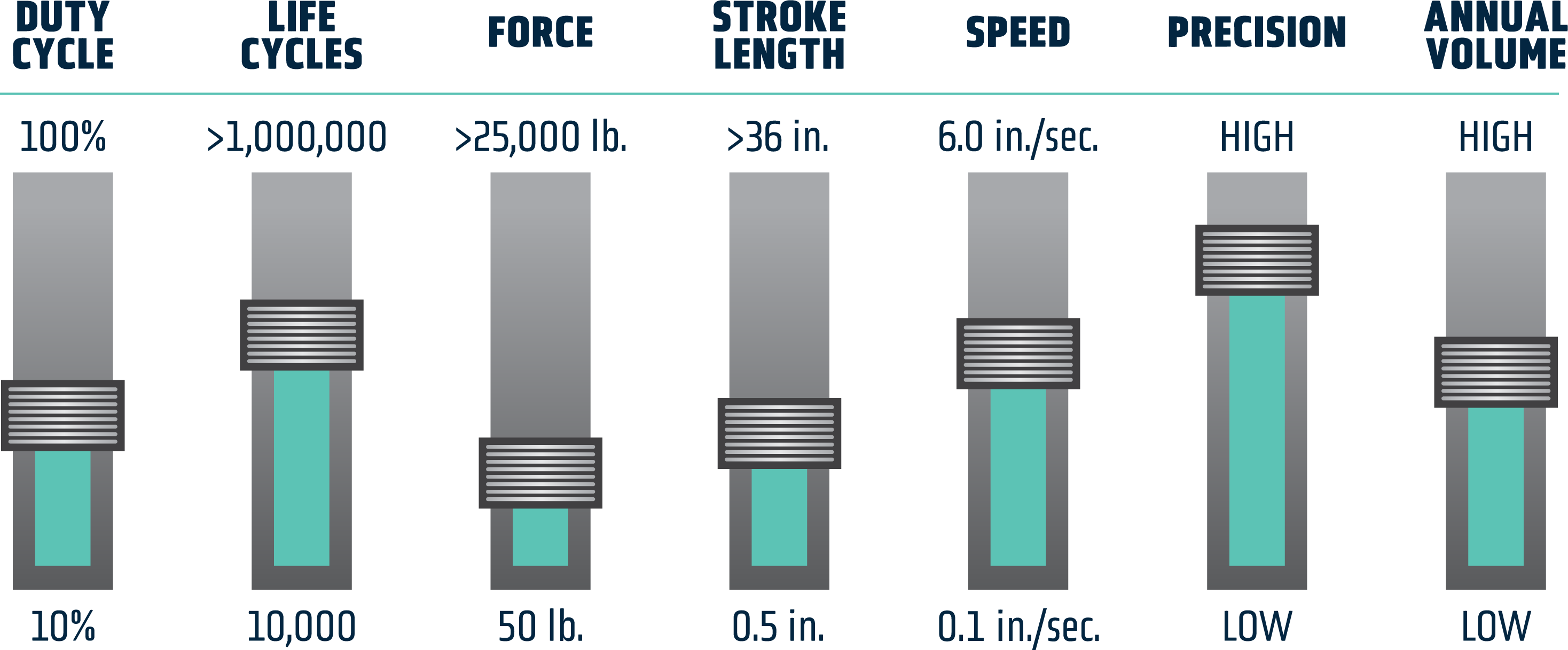

PEM initiated a project to design an alternate actuator that met the customer’s specific technical requirements, which included their desired electrical connector. The customer’s reputation and market success were built on quality and performance of their damper control system - so the actuator needed to perform flawlessly as well. The customer’s application directly affects the safety of scientific laboratory workers, so extensive product testing was required to satisfy the customer’s strict standards. PEM worked with the customer for over 5 years testing and perfecting the actuator’s performance and integration into customer’s overall production system. PEM slowly increased the percentage of the customer’s business over time – starting with 10% of the initial volume and eventually rising to 50%. The customer wanted to maintain 2 suppliers, so initially limited PEM’s share to 50%.

After initiating the relationship, PEM continued to work with the customer to improve the customer’s control algorithm, which did not always work with the other vendor’s actuator. When the other vendor began having delivery problems resulting from integration complications from a corporate merger, PEM was awarded 100% of the business.

Based on the success of the first application, the customer considered PEM for a second product application. The incumbent supplier provided a good product that worked well for the customer’s application for hospital room ventilation; however, the customer felt that the product was not priced competitively relative to the performance requirements. PEM was asked to quote the application. PEM’s solution provided the customer with a 20% cost price reduction, while materially improving the performance of the customer’s overall system. During consultation with the customer’s engineering team, PEM identified a way to improve the system’s speed by 100% while using 1/3 the amount of energy – significantly improving the overall system’s efficiency that provided significant benefit to the hospitals. PEM’s improvement provided the customer not only a material cost saving, but improved the product’s performance and customer’s brand image in the marketplace.

PEM is now collaborating on a third application with this customer. PEM is providing digital communications, on-board calibrations, and the control algorithm for a new product. PEM’s solution allows the customer to sell a product as a stand-alone solution to building control companies, which materially expands their available market.

PEM has worked very closely with this important customer over a 12-year period, providing the customer not only competitively priced products that work within their manufacturing processes, but have helped this customer extend its market leadership with cost-effective product innovations as well.