Windshield Control on a Cruiser Motorcycle

PRODUCT APPLICATION

Raising and lowering the windshield on a premium U.S. manufactured motorcycle.

COMPETITOR

Actuator system from a large Korean manufacturer.

COMPELLING EVENT

The windshield on a premier motorcycle manufacturer severely rattled while driving. Customer complaints were frequent to the point of damaging the company’s brand image. Delivery problems with the supplier compounded the growing quality issues. While customers and dealers pressured the company to fix the problem, the supplier wouldn’t help them address the problem.

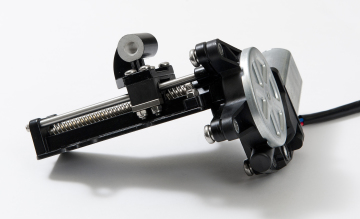

The company approached PEM to see if they could address the windshield’s rattling problem as well as to see if there were opportunities to reduce cost. PEM reviewed the existing design and studied the application in great detail. PEM proposed a completely different approach to the windshield actuator that addressed both the rattling as well as cost. PEM’s approach actually simplified the actuator’s design that focused on fewer, but higher quality components. PEM’s design included a unique motor that allowed dead-end control of the actuator. This motor choice allowed PEM to simplify the design by removing all of the limit switches as well as the control box. They were also able to get rid of all of the fasteners because of the approach – fewer moving parts combined with higher quality components meant greater stability and lower cost.

PEM reviewed the advantages of their design with the company’s engineering team. The company’s engineering team was skeptical that PEM’s design would meet the desired lifecycle requirements without the use of limit switches. PEM offered to build a prototype to demonstrate the operation and prove the design would meet the company’s needs, including the rattling problem and lifecycle challenges. The team’s agreed to move forward with a prototype for validation of concept.

PEM delivered a prototype of the proposed solution 3 days after the engineering meeting. The company immediately began testing the prototype. After 50,000 flawless cycles, the prototype was analyzed for wear. Testing proved the proposed solution to be viable and the design path was finalized.

PEM’s unique re-design solved a number of the company’s challenges. First and foremost, the design addressed the rattling problem. Second, the reduction in components simplified installation of the company’s plant and also simplified the windshield’s operation. Finally, the re-designed product achieved a 30% cost reduction from the competitive model while addressing all the quality issues.

PEM’s focused effort, combined with close collaboration with the company allowed the project to be completed in a short period of time. The time between initial prototype and testing of the first machined parts was approximately 6 weeks. The time between machined parts to production parts was approximately 4 months. In total, the time between discussing the initial problem to production was approximately 9 months.

Today, PEM’s actuators are on every model the company produces. PEM supports the company by stocking inventory against the company’s 9-month running forecast. PEM ships product to the company within 24 hours after receipt of an order.