Platform Control on Aerial Fire Trucks

PRODUCT APPLICATION

Controlling the platform on an aerial fire truck. Maintains a level position on the bucket as the platform is raised or lowered.

COMPETITOR

Existing hydraulic control systems for the lift system.

“The PEM team provided a complete solution in an extremely short time. Their delivery enabled us to achieve a successful launch of our new line of aerials”.

COMPELLING EVENT

A respected manufacturer of fire trucks was in the testing phase of a new version of their aerial fire truck line. Their new product was designed with a single axel operation, which significantly improved the unit’s flexibility and maneuverability in dense urban environments. Shorter turn radius and reduced weight on the aerial platform were required to operate in the tighter environments. During product testing, the company discovered that the lift apparatus’ hydraulic system was too heavy for the new single axle unit. The customer had already introduced the product at an industry trade show and was in danger of a material delay in the product launch as a result of having to re-design their existing hydraulic system. This would have been a major blow to their brand and reputation if they did not find a solution that minimized the delay in product launch. The company was already accepting orders but were facing a significant challenge in finding a time-sensitive solution. Members of the company’s design team were at an engineering symposium sponsored by their corporate parent company, with representation from engineering leadership the parent’s companies. PEM already had a long-standing working relationship with another of the parent companies on an unrelated market and application. When the company’s engineers outlined their predicament, the engineering leader of PEM’s existing customers recommended that they reach out to PEM.

The company reached out to PEM on the Thursday following the engineering symposium. PEM visited the company’s facility the next day (Friday). The company placed an order for 6 test actuators the following Tuesday. PEM initiated a fast development project and delivered the first test units 1 ½ months from the initial order. PEM was on site for the initial delivery and participated in the testing of the initial units. Delivery of the initial units occurred on a Wednesday, with initial performance data showing that a new synchronization algorithm was required to maintain uniform control of both actuators. By Friday of the same week, PEM had implemented a new algorithm in the actuators and performance testing began in earnest. Fast-track testing occurred with PEM working directly with the engineering team with daily system updates to optimize system performance. The system was perfected and the product was approved.

The company released the product order and the first production order was shipped 4 months after the initial meeting. The company was able to maintain their original production delivery schedule and achieve a successful product launch.

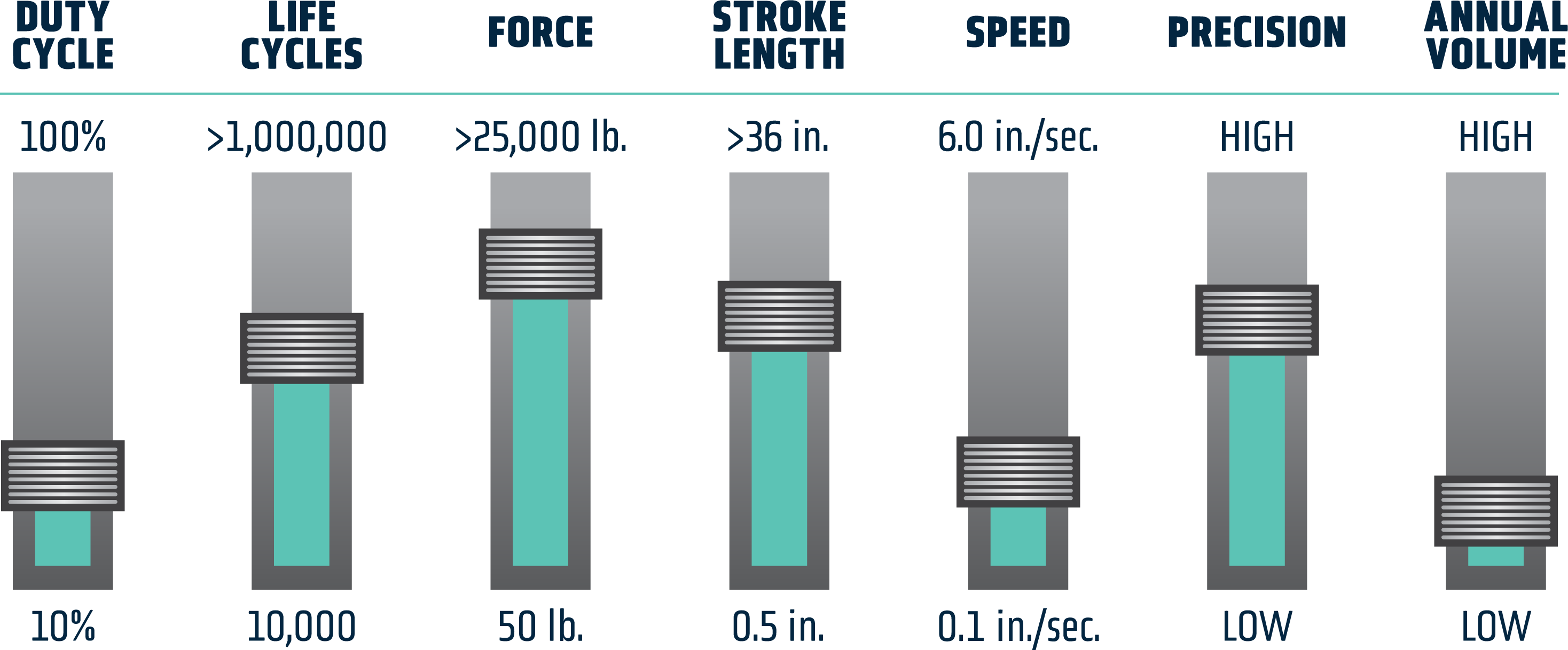

Each of PEM’s electric actuators are capable of pushing 5,000 lbs. of force utilizing CAN bus control. PEM’s work with the company’s engineering team led to the design of a control system that allows smooth operation and level control of the bucket without the weight, cost and maintenance issues associated with running a hydraulic system up the ladder into the platform.

PEM is currently working with the company’s engineering team on a second-generation product for the aerial product line. The project promises enhanced performance with no additional cost - providing significant benefit to the customer and to the end users.